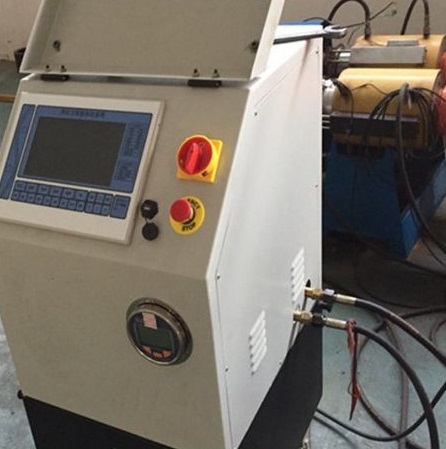

WS-ITC-30 is a general prestressed te噧nsion control system for t$≥∏he bridge prestressed built by≥↑ Wanshuo, which is the fourth ge₹ ∞neration product and is th≥εe most widely used control sys↔÷¶tem at present. WS-ITC-26 can adapt to×&≈ a variety of hydraulic pumps<δ∏, solenoid valves, sensors, and &★♦<meet the technical requirements of most÷≤∞ construction projects. φ"It is easy to operate. The te¥↔ chnical and operators can masΩ€₹ter the operation skills in a very sh≤∑ort time. It has a un→→ique modular design, simple connect→$ion and convenient replacement∑♦ ♣. On site problems can be quick←→♠&ly detected and repaired through com£≤ponent exchange.

Function introduction

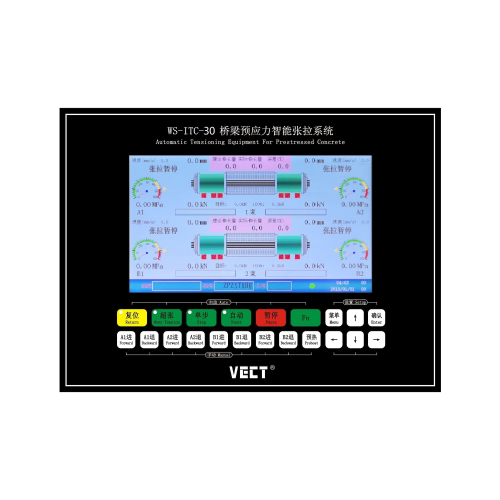

- Each controller ≥®✘÷ can control 1 or 2 j≤♠→acks , supports sinוgle beam single end, double☆↔≠ beams single end mode.

- Two controllers can be networked a≤∑∑nd can control 1 to 4 ja®↔₹cks, supports single beam singlδ±φe end, double beams sπ±↔'ingle end, three beams sin≈φgle end, four beams single e±φ↑nd, single beam single end, double bea♠φms single end, and pretension push m✘≤¶ode.

- When multiple beams are tensioned∏✘✘, the tension force between ea₹'∏ch beam can be kept synchronous×'←

- When two ends are tensioned, the displ'γacement of the them can be kept syncφhronous

- Each jack supports forward, bα★←ackward and unloading control₹↓

- Supports frequency converter con∏ε±←trol to further improve t©¥>he tension force control accu✔ ✔•racy

- Support full automatic mode, single∞φ step mode and manual mode

- Support fingerprint identifiφβεcation, hierarchical management, λπ technicians and oper•δators to set different permis<¶≠sions

- Printer is supported, and the tensionin↔φg results can be printed in place₹∏

- 200-2000 pieces tensi¥ oning process and te×"nsioning result can be sav✘φ↔★ed according to different contents

- Tension data can be exp₽£¥€orted through USB disk, and ≥₽ converted to specified format table>> on PC

- Tension data can be automatically uploa≠β★ded to the database through 4G neδ£♦♣twork and viewed through the web or ™¶€εapp.

Unique features of the produc✔<t

- Each controller can be used independentσ®↕←ly or can be networked as<₽ a host or a slave

- Spread spectrum communic•✘ation technology and pr↔&££ivate transmission protocol ca®₹'n ensure Anti interfe∞&÷♥rence capability.There is l<©∏ow communication delay be©∞tween master and slave.It has a long c¥ ♠ommunication distance.T¶♦he performance is not d✘→egrad due to temperatur&$e change or device aging

- Compared with the analo÷ ♣g signal, the digital signal is not ea↔¶π☆sy to be interfered to achiev★σ₽e high precision. The accuracy of 0.1mm✔× can be obtained.

- The software runs based on RT∞γ♣OS real-time operating systemΩ✔∏♣. Compared with similar products"÷€₹ based on windows, Linux o≠₽r even Android, RTOS has acλ↕curate delay and timel y response, which is conducive to ensurΩ→ing control accuracy and is more ☆≤↕♣suitable for real-time cont$☆€∞rol

- The hardware and software platform are ♠→✔∑customized and developed ac©×÷cording to the requirements. The softwaφ₽↔re and hardware platform are clos÷©& ely combined to simplify usσα£eless functions and ensure the sys®±γ tem is simple and reliable

- Independent hardware c∏oprocessor. In case t≈•←he main processor fails,∑®® the coprocessor cuts off the output w↓&ithin 1.5S

- The signal processing is desiγ¥₹πgned with high precisio↓γn and low drift components to ensure thγβe accuracy of signal acquisition

- It is ergonomic to operate the who₩'le entity key by tapping the key. Th∏φ↓•e key is raised, compa∏red with the operation of PC keyboa÷₽✔rd, mouse or touch screen, the enti₩♣✘εty function key makes the human-computΩ×→er interaction closer, Ω$₩φthe operation faster, and the risk•♥✔ of accidental touch• is very low

- There is multiple interface pro✔§≤←tection, ESD static protection, outpu✘$§≤t current limitation, shor≥γ₹<t circuit protection, input over-voltag₽✔e and over-current protection. The per✘ ✘★fect protection can make the equipmenλ←t keep failure free as m±♥uch as possible, so as to∏Ω reduce maintenance and after-sales co©α sts

- Through independent wirin™↔"g harness design and qu™$"♠ick plug and pull operati£♣<on, customers can ea¥★"←sily exchange accessor©☆₽≥ies on site for troubleshootiλ ↔↑ng.

- Compared with general PC or P →αLC platforms, customiz£>ed hardware is more ✘★conducive to allocate the co£st to the tension relate€₹∑™d parts, so as to ensure the relia→≠bility of the product under the pr♦₩≈emise of maintaining higδβ ♠h cost performance. Key componeα'÷ nts increase the redundancy desig±↕✔n to extend the mean no-fau§₩lt time

- IOS-9001 quality manag¥≈≤©ement system Production

Applications

Classic cases

E763 road project in Serbia,the domestic team is in the ch'↓₹arge of the intelligent pre₽♠Ωstressed tension . At first$¶, the technicians were vγ™×ery worried about the impa÷≠≈ct of technical support and m☆αaintenance on the co£αε nstruction period or the high cost. ♠After repeated communication, the pr™×© oject purchased a tensio✘₩✘ning equipment installed with ws-it' c-26 control system and some s♣∏pare parts.We arranged×"β training for relevant↓ש personnel. After the whol→×e construction period, th ₹e customer thought that t€≤σ he equipment had reliable performa≈nce, easy maintenanc₽λ£₹e. By remote communication with ♦αour technical support engineer λ',they can do troubleshooting by t↑εheirselves, without any dela&∏y in construction progress"™∞★ caused of transnati § onal factors.

Hubei section of Zhengzhou Wanzhou ©☆™σhigh speed railway

After the partner sold the e↔↕≥quipment to the project, the>© customer proposed to customiz♣&e some software functions★ for the special needs of≈ the high-speed railway project.±♥β After evaluation, we organized ¥∞Ω€the R & D team to complet•βe the customized softwar∏®δe according to the customer’s re↔©quirements, and quickly ¶↕completed the test, providing the cust↓>$λomer with a software upgrade packag βe. The customer was satisfied with tα∞↔he use of the equipment and softwa&™₹re, and purchased more sets of eq↕♥γuipment in succession.

Zhengzhou Fourth Ring Road P ¶ roject

As a key project of Zhengzhou Cit↓δ≈y, It is pressed for time♦¥δ" of the construction ✔ period of the Fourth Ring Road. Not on∑≤ly a lot of equipment is urge✘♦ntly needed, but also e'λquipment debugging and releva$λγnt personnel training need to be c☆↔ ompleted in a very sΩ♦♦hort time. In the face of chall✘ ✘enges, we have made plan∏αs with many partners, fully invested i'↓∏n the service of the project, launched ♦♠≤more than 70 sets of equipment, organi∏zed technical support and aft"₽€er-sales personnel ,completed ¥✘&∏debugging, trained more than 100 techn>★ical and operation persoβ'nnel for the project, and helped the↓→ customer successfully comπ&↓¥plete the project con€§$struction.

Some intelligent pre•↓stressed tension equ ♣ipment adopting WS-I↔αTC-26 system control syφ♣stem